We streamlined and automated the business processes of Tropical Organic Growers by developing a traceability system for their products and logistics operation.

Client

Industry

Agrícola Industrial

Services

Discovery

Behavioral Process Design

Process Automation

Business Intelligence

The challenge

Rethinking processes for automation

TOG is a company dedicated to sustainable agriculture that produces and sells organic tropical fruits, mainly organic bananas. The company, located in the state of Colima, has been in existence for 5 years and has some 500 hectares of production.

TOG, driven by an innovative vision, has the challenge of professionalizing the agricultural industry, which is in general not digitally mature. As a relatively new company with growing plans, they were looking for a new way of organizing that would allow them to eliminate friction between their different touch points in order to become more agile. Their goal was to optimize their processes and automate them to increase productivity and help teams become more efficient with their work.

When considering process automation, they had a twofold objective:

Product traceability: From production in the fields to delivery to the customer and after-sales service. With this insight, the company could be clear about the origin of a product, the person responsible for supervising a packaging shift or the production in each of the farms, among other key processes. Having this data would enable companies to be more agile in investigating problems that may arise in the process.

Improve operational process planning: In this industry there are daily changes depending on the weather, and being at the whim of external factors, the flexibility to react quickly is necessary. Therefore, it is essential to understand the daily productivity in each of the farms to know where to get the product requested in the purchase orders, and to be able to anticipate possible shortages or overproduction.

In this context, Multiplica was approached strategically to rethink the current processes and find the best automation platform for their technical needs.

‘When launching the project, TOG’s open-mindedness and willingness to rethink its processes by establishing the touch points and actions that needed to be changed to adapt to the needs of an automated process was key.’

What we did

Creation of SIPOC Diagrams

We started the project with a Discovery phase in order to understand the key stakeholders and their role in the project, clearly define expectations and work methodologies.

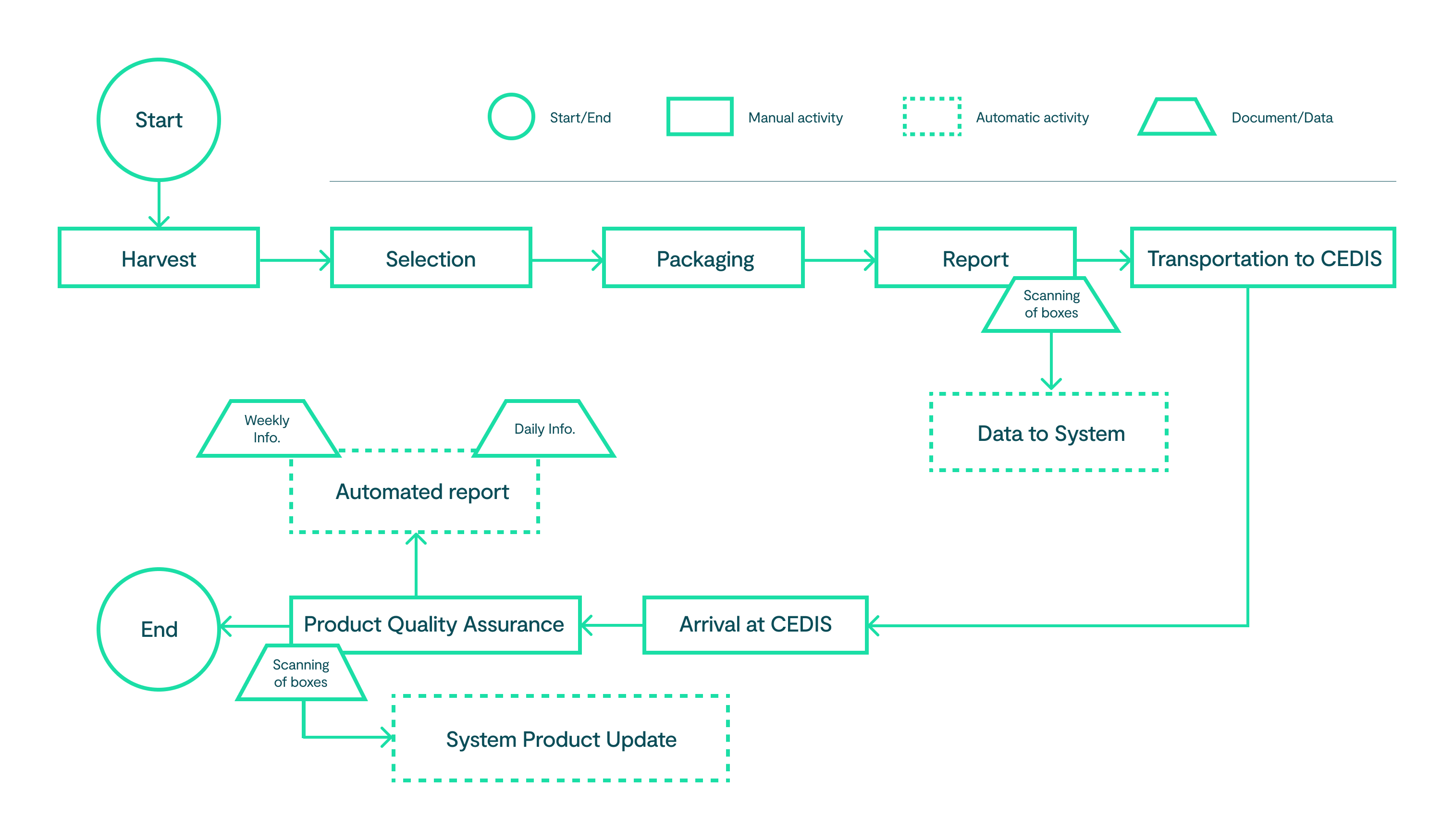

From there, TOG’s current processes were closely followed in order to understand in depth all the elements involved in each of them. Due to their complexity, to perform the mapping, we segmented them into 4 key processes:

- Planning: Generates the strategic task orders for each of the other key processes.

- Farms: In charge of cutting the fruit, packing and assembling the pallets for shipment in containers to the CEDIS (Distribution Center).

- CEDIS: Receive the product from the different farms, store it in refrigerated chambers and prepare it for shipment to the final customer.

- Logistics: Responsible for the process of the product leaving the CEDIS until it is delivered to the customer.

Key learnings

The importance of creating a comprehensive data model that allowed us to analyze the data we had and determine how to arrange it on the platform.

We improved our work methodology for marketing automation projects by dividing it into four distinct phases: immersion, strategic proposal, data integration, and implementation.

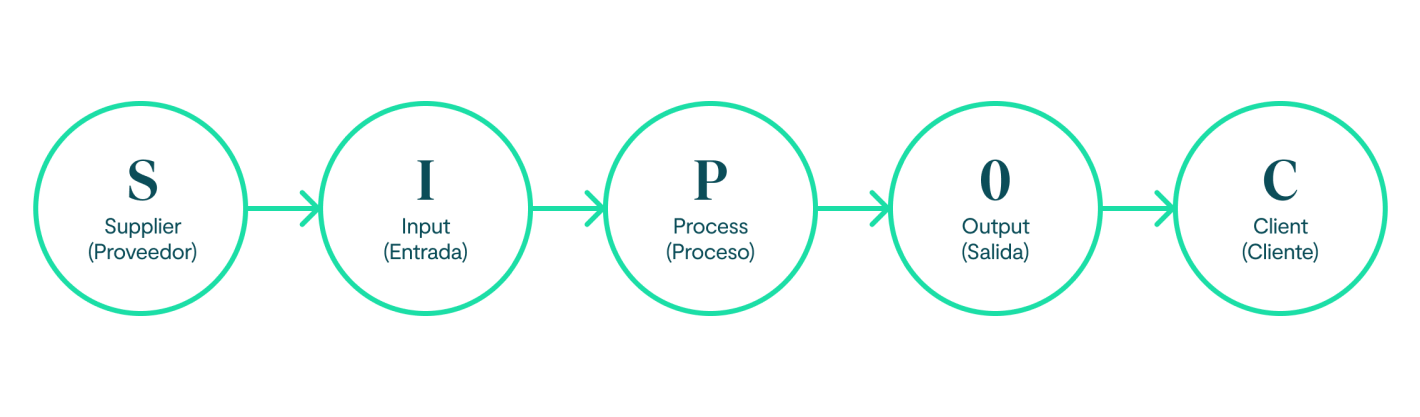

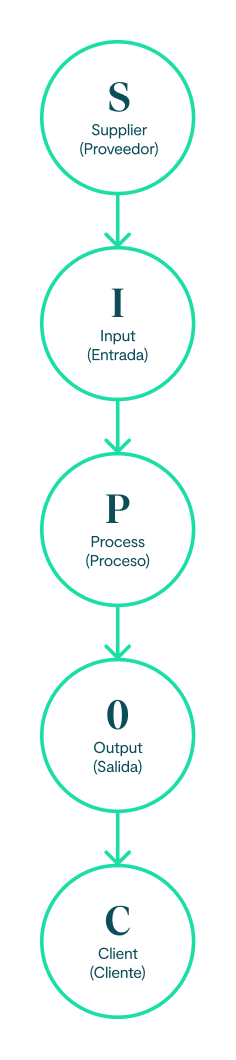

Subsequently, we drew up SIPOC (Suppliers, Input, Process, Output and Client) diagrams that allowed us to trace a process through the documentation of suppliers, inputs, processes, outputs and clients. In this way, we obtained a flowchart in which the areas and people involved in each stage of the process are shown.

With the definition of these diagrams, a platform is chosen with which the implementation is going to be carried out. At Multiplica, we select the most appropriate platform for each project, considering factors such as the complexity of the processes, size of the company, its price and its functionalities, among others.

TOG’s requirement was to find a platform that could fully integrate with their SAP, without having to migrate to another platform. The project required a high level of customization without excessive licensing costs, as well as mobile functionality for all staff. For this reason we decided on Zoho Creator.

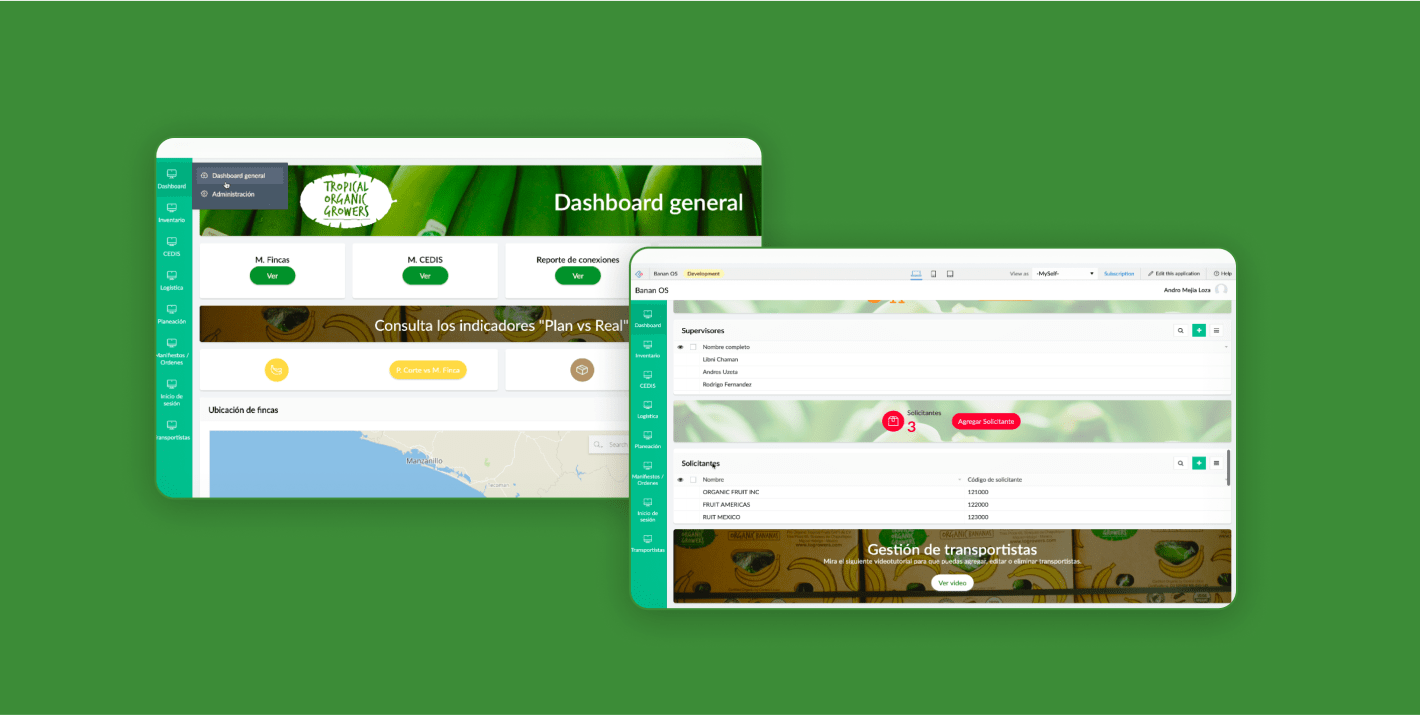

Platform design and integration

From there, the platform was designed based on behavioral design, taking into account the lack of end-user experience in the use of platforms, and creating a very intuitive interface and processes, so that the learning curve of use would occur rapidly and the user would be able to work autonomously.

In this way, a SAP platform integration was carried out, working side by side with TOG’s IT team, to generate the forms, information connections, interface and validations, among other functionalities. At the same time, we integrated it with Zoho Analytics to collect and analyze the data. This tool – ideal for business intelligence analysis – allows us to create dashboards, reports and graphs that facilitate decision making and maintain the flow of information where and when it is needed. It also has excellent usability and an attractive interface.

Subsequently, a key profile was defined in the company to perform the role of champion in the team to monitor the usability of the platform, train the team and ensure the correct use of the platform.

Key Learning

A fully involved client is a key differential for a successful project. The synergies we created with TOG and their active participation in the project were vital for working together, making decisions collaboratively and arriving at the best solution.

Resultados

Andro Mejia,

Business Development Manager at TOG

Destacamos

Empathy with users.

A user-centric vision for professionals not accustomed to the use of digital platforms.

Openness to change.

Working with flexibility on our part and that of the client to adapt to the changes that arose.

Technology agility.

Implementing low-code technology to have a customized and user-friendly application.